How WEST SYSTEM Got its Start

through the eyes of meade gougeon

The Early Years

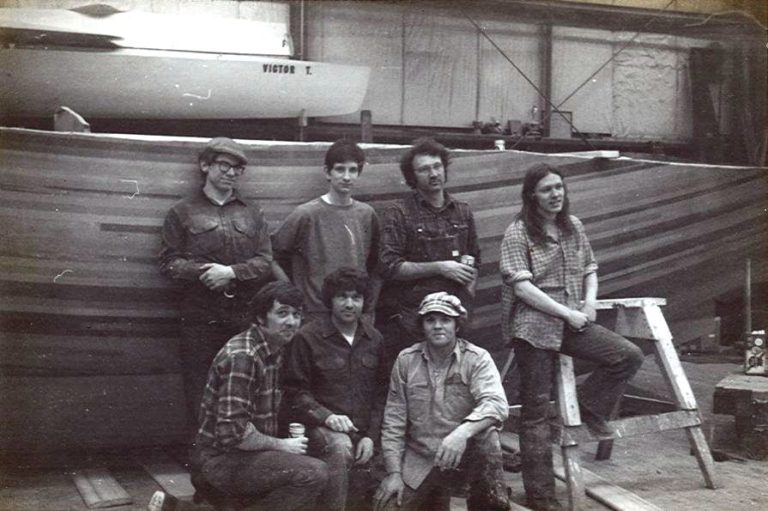

My brothers and I were avid DN iceboat racers growing up on Lake Huron’s Saginaw Bay. Post-World War II was a period when boats were hard to come by. In order to compete, we built our own boats. The DN iceboat, with its highly loaded components continually operating at strain rates just short of failure, proved to be an excellent testbed and contributed greatly to GBI history.

In 1959, my youngest brother, Jan, began an apprenticeship as a boat builder for Victor Carpenter. Jan was 14 and spent his time after school and on weekends helping Vic build boats. Vic had been a patternmaker in the Detroit auto industry. He had seen the switch from using resorcinol glues to epoxy adhesives for laminating pattern stock. Because the epoxy required less clamping pressure, it was now possible to bond large structures efficiently and at low costs. Vic became enamored with this technology and was the first professional boat builder to use epoxy and traditional fasteners to assemble wooden boats.

The things Jan learned from Vic at an early age proved crucial to our later work in boat construction and epoxy development. This technology challenged our imaginations and led us down a path of trial and error over the next ten years. In this time, we built a series of five racing trimarans and numerous DN iceboats. Our goal for each of these projects was to build the lightest structures possible while minimizing the use of fasteners. We wanted to produce race-winning boats. Our emerging, lightweight wood/epoxy technology quickly developed as an advantage over the best fiberglass technology of that time. By continuously working to innovate and push the limit of material performance, our knowledge and skills grew. We learned from both success and failure.

1969

In 1969, we began building DN iceboats as our first commercial product. Over the course of five years, we would sell more than 200 iceboats.

The epoxy system we were using worked well as an adhesive but was difficult to apply as a coating. Lucky for us, Herbert Dow, the grandson of The Dow Chemical Company’s founder, was an avid sailor who we introduced to iceboating. After seeing what we were up to, Herb made it possible for us to work with several chemists in Dow’s epoxy lab to help us refine our epoxy resin and hardener formulations to be used as both an adhesive and a coating.

It was well known within the industry that epoxy-based technology had the potential to create a formidable moisture barrier, and now we were able to both bond and seal the wood of our racing trimarans and DN iceboats with epoxy. We had developed the formulations that were the basis of WEST SYSTEM.

GBI historic moments

Part 1: Chasing Speed

02/15/1969

DN Iceboats

Brothers Meade and Jan Gougeon begin building DN class iceboats with wood and epoxy, selling 200 iceboats between 1969 and 1974. “Where we got really lucky in our quest for epoxy technology was to be located 17 miles east of Dow Chemical Co. We introduced Herbert Dow (an avid sailor and the grandson of Dow Chemical’s founder) to iceboating. Herb made it possible for us to work with chemists in Dow’s epoxy lab, helping us to develop resins and hardeners we could use as both an adhesive and a coating,” company founder Meade Gougeon says. With Dow’s help, the Gougeon brothers develop the formulations WEST SYSTEM epoxy products are based on.

07/01/1970

Adagio

The trimaran ADAGIO is launched. She’s the first large, all epoxy bonded and sealed wooden boat built without the use of fasteners. Meade and Jan Gougeon built her in just six months. She’s been sailing on the Great Lakes ever since and continues to be a serious contender in the Mackinac races. ADAGIO is proof that fully bonded monocoque structures can be built to last for generations.

January, 1971

WEST SYSTEM is Born

Word travels fast about the high-strength composites the Gougeon brothers were building with wood and epoxy. Local boat builders flocked to Gougeon Brothers Boatworks—located on the west side of the Saginaw River in Bay City, Michigan—seeking epoxy for their own projects. With an investment from middle brother Joel Gougeon, who had saved his earnings over four years of flying combat missions for the airforce in Vietnam, the brothers begin packaging their special epoxy formulation to satisfy increasing demand.

Part 2: A legacy in the Making

March, 1972

The Technical Manual

The first WEST SYSTEM Technical Manual is published. It helps customers understand WEST SYSTEM epoxy products, which are like nothing else on the market at that time. The manual will be expanded over the next several years and is the first in a long line of informative publications for epoxy users.

January, 1973

Iceboat Production

Gougeon Brothers Boatworks improves the performance of DN Iceboats by building them with wood and epoxy. Their boats win races due to the added stiffness and durability the epoxy provides. By 1973, the brothers’ small boat shop on Martin St. in Bay City, Michigan becomes the largest builder of iceboats in the United States. Even so, in 1974 they sell it to focus on epoxy.

May, 1973

Golden Dazy

Construction begins on GOLDEN DAZY, the Ron Holland-designed monohull. She goes on to win the 1975 Canada’s Cup and is still sailing today in upstate New York. The success of these wood/epoxy composite boat is revolutionary to builders and designers. They’re building stiffer, stronger hulls without increasing boat weight.

February, 1975

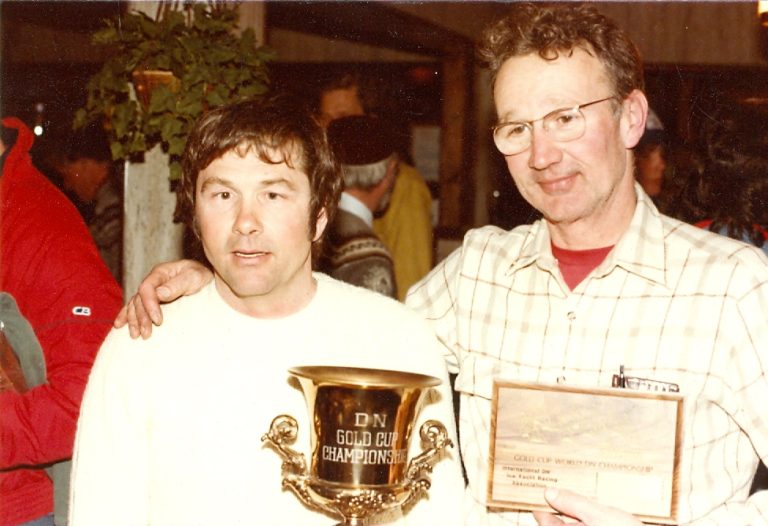

DN World Cup

Jan Gougeon takes 1st Place in the DN Iceboat Gold Cup World Championships, beating the fierce sailing Russians, Poles, Dutch, and Swiss. His DN iceboat is a plywood/spruce structure that is highly loaded and a great test of epoxy under stress. Jan goes on to win many more iceboat championships over the coming decades.

July, 1976

Hot Flash

The Gougeon crew uses cold-molded construction methods to build HOT FLASH, a 32′ half-ton monohull designed by Gary Mull and built on commission for the Usnis brothers of the Bayview Yacht Club in Detroit.

March, 1977

Rogue Wave

The brothers began building ROGUE WAVE, a Dick Newick designed 60′ trimaran for Phil Weld.Weld’s hopes to race it in the 1980 OSTAR are dashed by a rule change.

June, 1977

Flicka

1977 is also the year construction starts on FLICKA. Jan would spend four long days in the capsized FLICKA in the Atlantic Ocean during a qualifier for the next OSTAR challenge. He had plenty of time to think about the development of a self-righting trimaran before he was rescued by a passing freighter. Sadly, FLICKA had to be abandoned at sea.

July, 1977

The Boatbuilder

The first issue of The Boatbuilder is published. This black and white, 8-page newsletter about epoxy and epoxy projects will eventually grow up to be the 28-page, full-color Epoxyworks Magazine.

May, 1978

Slingshot

The Gougeon Brothers are commissioned to build SLINGSHOT, 60′ proa/trimaran, for Karl Thomas of Troy, Michigan. The purpose was to challenge the World’s Sailing Speed Record in England. Designed by Georg Thomas, it features a flattened after-section for planing and can reach speeds of over 40 mph.

July, 1978

NASA Project

Gougeon Brothers, Inc. manufactures laminated wood specimens for use in NASA’s Wind Energy Project Office. Tests are performed to determine the strength of an epoxy bond between a threaded steel rod and a laminated wood specimen. The mean value for the 15″ stud depth laminated for veneer specimens is 64,800 lbs of load, well in excess of the 38,000 maximum load expected on wind turbine blades.

June, 1979

GBI on Boat Construction

The Gougeon Brothers on Boat Construction is first published. The boatbuilding guide details composite construction techniques using wood and epoxy. It quickly becomes a favorite resource for professionals and first-time builders.

January, 1980

Splinter

Jan designs and begins to build Splinter, a developed plywood trimaran designed to be rightable after a capsize. SPLINTER was the second boat, after ADAGIO, that the Gougeons built with a wingmast. Jan places first in the Port Huron to Mackinac race aboard SPLINTER in 1981, 1982 and 1983 and also sets a record for the fastest finish. SPLINTER is still racing on the Saginaw Bay.

March, 1980

38 Knots

Racing SLINGSHOT in the ditch in Texas City, Texas, the crew (consisting of Mike Zuteck, Olaf Harkin, Peter Harken, Jan Gougeon, Dan Reichelsdorfer, Ron Sherry, and John Maudlin) posted a speed of 38 knots. But during a storm—with winds over 50 knots—Slingshot came loose from her mooring, hit a breakwater and broke into pieces. All that remains of her is a section of the bow which hangs in the Gougeon Brothers boat shop.

Part 3: Setting the Foundation for Future Success

January, 1983

Employee-Owned

Gougeon Brothers, Inc. undertakes the groundwork for becoming an employee-owned company. Any full-time Gougeon employee you speak with is a part-owner of the company and has a vested interest in keeping you as a satisfied customer.

January, 1984

MTS Machine

Gougeon Brothers, Inc. obtains an MTS testing machine, which exerts gradually increasing loads on test samples and accurately records the amount of deflection at sample failure. Today, our lab includes 2 MTS machines, 3 DCSs and a DMA for thermal analysis, FTIR for analyzing composition, a TGA for characterizing the thermal decomposition of materials, and a Rheometer for measuring viscosity.

May 1984

Ollie

OLLIE, the prototype STRESSFORM 35′ trimaran designed by Jan Gougeon and Built by Gougeon Brothers, Inc., is launched. She will sail successfully for decades to come.

May 1985

Wind Blade Turbines

Production of 65′ long wind turbine blades for Westinghouse begins in GBI’s Bay City plant. When erected, the wind turbine sweeps a 142′ diameter and produces 600 KW of power in winds of 28 mph.

November 1986

Repair Kits Introduced

WEST SYSTEM Handy Packs and Maxi Packs hit the market to meet customer demands for smaller packages of epoxy. The self-contained repair kits retailed for $3.95 and $11.95 respectively, while Ronald Reagan was president.

January 1987

Fiberglass Repair Manual

The first edition of the popular Fiberglass Boat Repair & Maintenance is introduced. The illustrated manual offers a variety of fiberglass boat repair techniques and retails for just $2 in 1987. The up-to-date version is now available as a free download on this website. or in print at fine marine chandleries.

April 1988

Adrenalin

ADRENALIN, a Formula 40 trimaran, is built of wood, epoxy and carbon fiber by Gougeon Brothers for Bill Piper of Ossineke, Michigan. She takes an extremely close second place in her first regatta in the Formula 40 Grand Prix circuit in Brest, France in April of 1988.

November 1988

Laminating Epoxy

Gougeon Brothers, Inc. introduces Gougeon Laminating Epoxy (GLR/GLH), the precursor to their PRO-SET® line of OEM epoxy products. Among many high-end projects, GLR/GLH is used in building offshore powerboats like POPEYE’S DIET COKE® by Goetz Custom Yachts. PRO-SET epoxies have been used in the construction of high-speed powerboats ever since.

January 1989

410 Microlight

Lightweight, inexpensive 410 Microlight Fairing filler is introduced. This is an easy to mix, sand and shape epoxy filler that stores nicely even in humid environments. The product reduces the hassle of sanding and fairing for epoxy users worldwide.

April 1989

Siberian DN Victory

Jan Gougeon enjoys Russian hospitality and a victory in the 1989 DN Big Cup of Siberia, placing 1st overall in the 7 races of the Gold Fleet Regatta. “While there was some difficulty with the language barrier, we had a lot of fun learning from each other,” Jan said. He is 44 years old and a 3-time World DN Iceboat Champion at the time of his big Siberian win.

April 1990

Gougeon 32

The water-ballasted, shoal-drafted, trailerable and streamlined Gougeon 32 Catamaran is developed for production. There are still Gougeon-32’s competing in regattas today, including Russell Brown’s “Icognito“.

September 1990

Wooden Boat Manual

Wooden Boat Restoration & Repair is published, illustrating professional-level repair techniques for wooden boat enthusiasts. This popular manual is now available as a free, downloadable PDF on this website (under Instruction) and print copies can be purchased at fine marine chandleries.

February 1991

DN Gold Cup

Jan Gougeon takes his 4th DN World Gold Cup, placing 1st overall in the 5 races of the International DN Ice Yacht Racing Association (IDNIYRA) Gold Fleet Regatta on Lake Huron’s Saginaw Bay, Feb. 3-4, 1991.

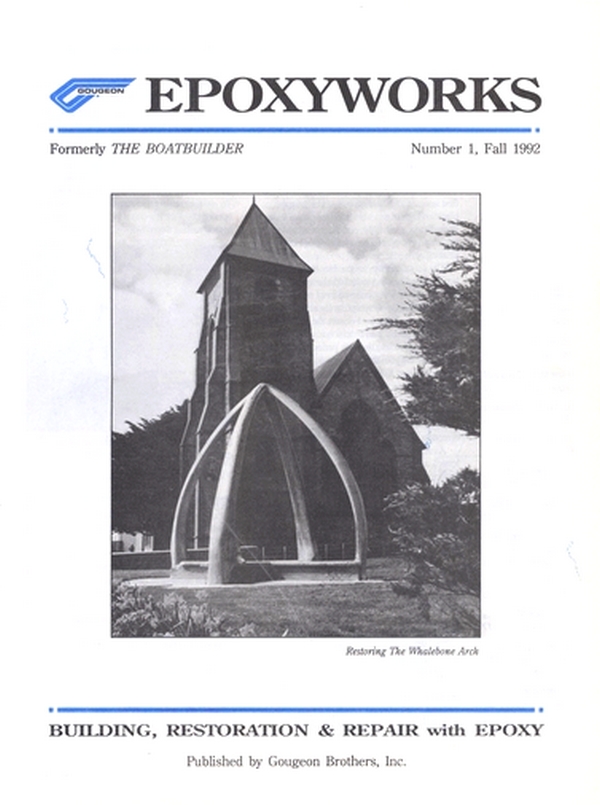

September 1992

Epoxyworks

Epoxyworks Magazine debuts. After 15 years of growth in scope, size and popularity as The Boatbuilder, the 26-page biannual publication evolves beyond boat construction to encompass all types of building, restoration, and repair with epoxy. The cover feature is the restored Whalebone Arch at Christ Church Cathedral in Stanely, Falkland Islands.

October 1992

Pocket Rocket

POCKET ROCKET, Jan Gougeon’s personal prototype of the Gougeon 32 (or G-32, or as it was briefly known, Hummer) production catamaran, ends the racing season undefeated for line honors. The boat places 1st in the singlehanded Port Huron to Mackinac Race, the Lake Huron Double Handed Challenge, and the Buzzards Bay Regatta.

October 1994

PRO-SET Epoxy

The brand name of Gougeon Laminating Epoxies is changed to PRO-SET Epoxies. These OEM epoxies set new standards in room-temperature cured, post-curable laminating and infusion epoxies and continue to grow in popularity among high-end composite builders.

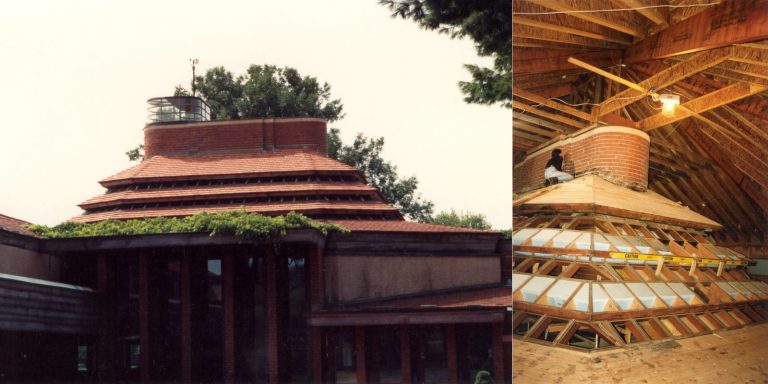

April 1996

Wingspread

The 1938 Frank Lloyd Wright-designed, 14,000 sq. ft. residence Wingspread (Racine, Washington) undergoes extensive stabilization and roof repairs using PRO-SET Epoxy products from Gougeon Brothers, Inc., as well as materials testing and guidance from GBI’s technical department.

January 1997

Antonisa

Hodgdon Yachts, Inc. in East Boothbay, Maine begins cold molding ANTONISA, a 124′ sloop of mahogany and WEST SYSTEM Epoxy. The carbon composite mast is 172′ tall. Completed in 1999, ANTONISA weighs in at 350,000 pounds. The salon features a marble fireplace and a pipe organ.

January 1998

Tenacious

The Jubilee Sailing Trust begins constructing the world’s largest wood/epoxy tall ship underway: TENACIOUS, a 65-meter (250′) 3-masted barque. Based in the United Kingdom, the Jubiliee Sailing Trust helps integrate physically disabled people into sailing aboard TENACIOUS. WEST SYSTEM Epoxy is used throughout the construction.

September 1999

Hydromat Test

The Hydromat Panel Test, a Gougeon-developed structural test using a self-contained pressure bladder, becomes the American Society for Testing and Materials (ASTM) standard D6416. The test evaluates the performance of sandwich composites, plywood, or flat plates of almost any material. The pressure bladder represents more realistic loading pressures than earlier ASTM standard tests for these qualities.

April 2000

Serendipity

SERENDIPITY, a modern decked sailing canoe, is built by Hugh Horton for Meade Gougeon using wood, epoxy and composite Kevlar® components. The rig has a simple and efficient reefing system.

January 2001

Scheherazade

Hodgdon Yachts in East Boothbay, Maine builds SCHEHERAZADE, a 155′ Bruce King-designed wood-epoxy ketch. She’s cold molded with multiple layers of Douglas fir, western red cedar, and WEST SYSTEM Epoxy.

April 2002

ISO Certification

Gougeon Brothers, Inc. completes the arduous process of certification under ISO 9001:2000 Quality Standard. The standard represents a quality management system that pervades all elements of the business, giving structure to a whole dynamic of customer service.

Part 4: Making Bonds that’ll Last a Lifetime

April 2003

Babyface Nelson

BABYFACE NELSON is launched on Gull Lake following two years of cold molded construction in mahogany and WEST SYSTEM Epoxy. Built by Bruce Hutchinson, the boat is a replica of Gold Cup racer BABY BOOTLEGGER, designed by George Crouch in 1924.

February 2004

Scaled Composite begins using PRO-SET Epoxies

Scaled Composite in Mojave, California begins using PRO-SET Epoxies in the development of their cutting-edge spacecraft such as SPACESHIPONE, PROTEUS, VOYAGER, CAPTIVE CARRY (shown), and ADAM. Scaled’s founder, renowned aerospace engineer Burt Rutan, began using WEST SYSTEM Epoxies in moldless composite construction homebuilt aircraft in the 1970s.

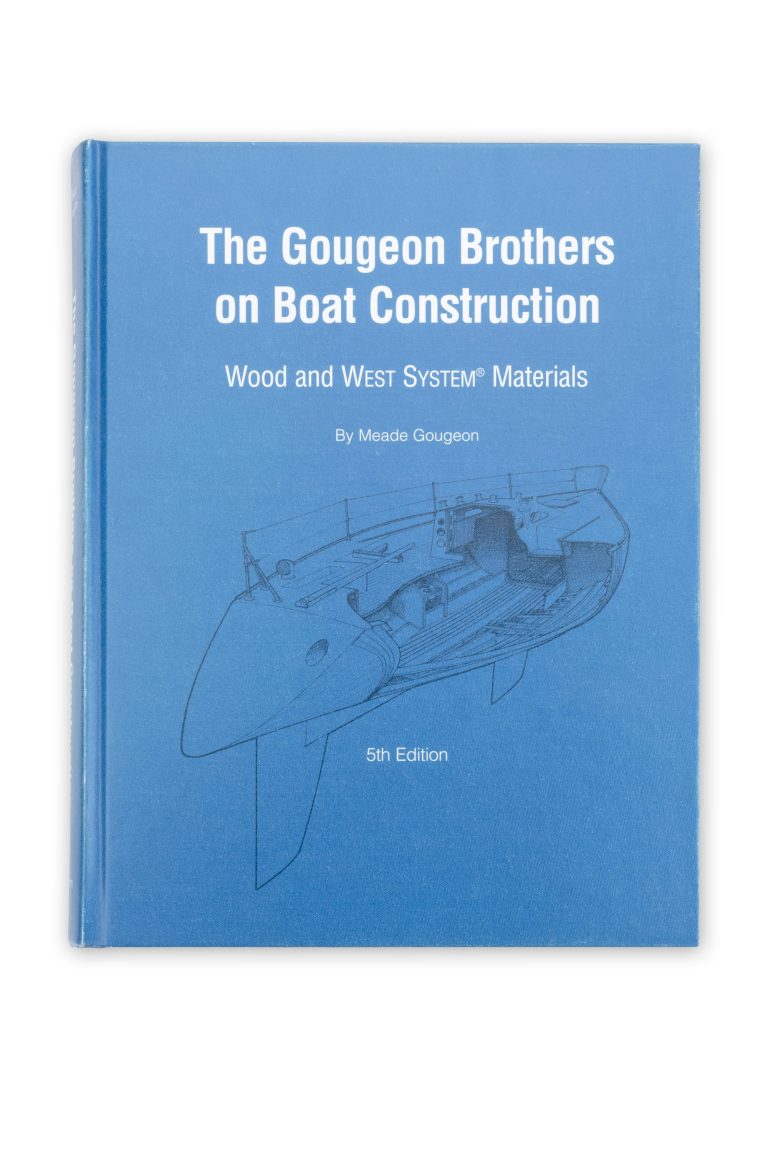

April 2005

5th Edition

The 5th Edition of The Gougeon Brothers on Boat Construction is published. It is expanded by 20% with new material, a revised layout for easier navigation, and is updated to reflect evolving epoxy technology.

August 2005

Gougmarans

Meade and Jan launch their Gougmarans: lightweight, shallow-draft, efficient power catamarans on Dick Newick-designed 32′ hulls. Jan’s is christened MAGIC CARPET, while Meade’s is simply called GOUGMARAN.

April 2007

G/flex Epoxy

G/flex toughened epoxies are introduced. The innovative products are rubber toughened and bond tenaciously with many types of plastic, aluminum, and hardwoods. They’re are resistant to the stress of expansion, contraction, shock, and vibration. These specialty epoxies come in an unthickened (G/flex 650) and pre-thickened (G/flex 655) form and are available in sizes from 8-oz kits to 50-gallon drums.

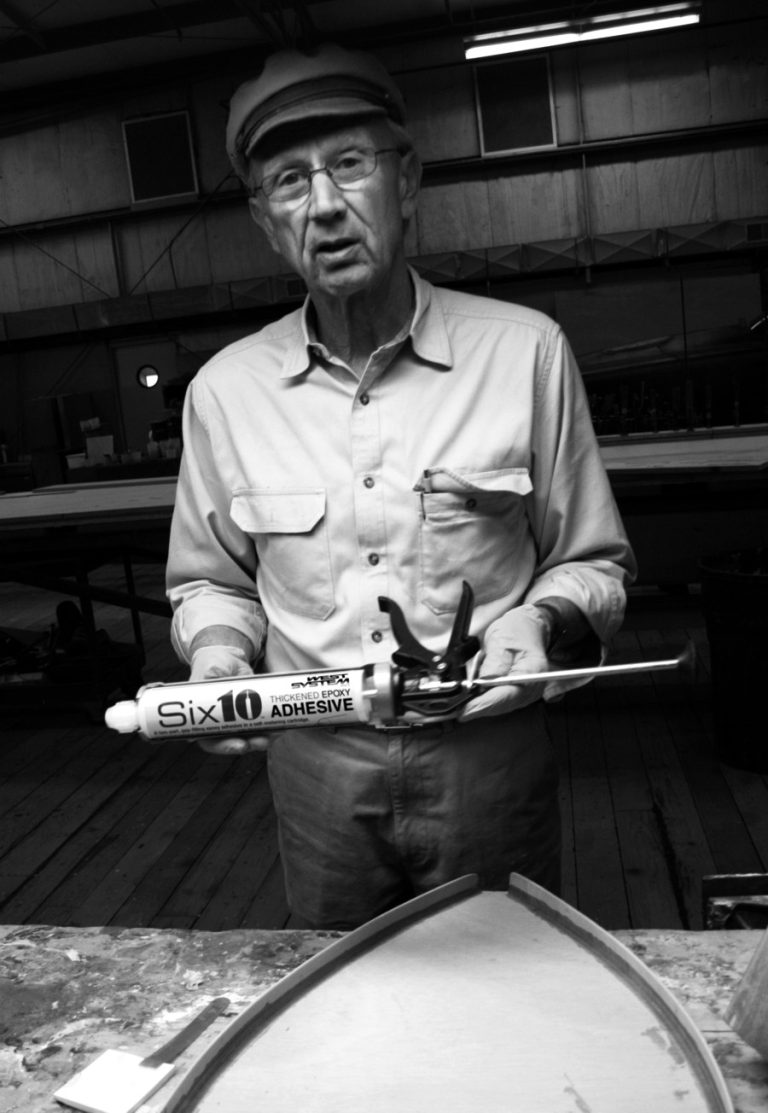

September 2008

Six10 Introduced

Six10 Thickened Epoxy Adhesive, a 2-part epoxy system in a chambered, self-metering cartridge designed to be dispensed with a standard caulking gun, is introduced. Its convenience and versatility make it an immediate hit with first-time and seasoned epoxy users.

August 2009

40th Anniversary

Gougeon Brothers, Inc. celebrates 40 years in business with a big summer barbecue party, complete with a live band and fireworks. Friends and colleagues from around the globe join in the festivities.

April 2010

Zogo

ZOGO, a hybrid diesel/electric launch designed by Stephens, Waring & White and built by French and Webb in Brooklin, Maine, is launched. This craft pushes the envelope for high-efficiency, low-impact boating. She burns just 1.5 gallons of fuel per hour cruising at 10.5 knots.

January 2011

Hot Canary

The Gougeon Brothers technical staff builds the i550 HOT CANARY, an 18′ sport boat to be raced in the Everglades Challenge. The i550, designed by Chris Beckwith, is a small but substantial boat that can handle rough seas.

July 2011

Strings

Jan Gougeon launches STRINGS. Ten years in the making, sometimes referred to as Project X, the 40′ boat is essentially a folding catamaran with a fuselage. Jan designed STRINGS to be easy to sail solo, self-righting, and trailerable, with a shallow draft, yet a big enough footprint to be a serious offshore contender. Sadly, it is to be Jan’s final boat.

March 2012

Portola

Greg Hatten’s replica of the river dory PORTOLA completes a 24-trip down the Colorado River through the Grand Canyon, surviving some of the biggest white water on the planet for an almost 300-mile maiden voyage. Hatten built PORTOLA of wood and WEST SYSTEM Epoxy.

December 2012

Jan C. Gougeon

August 7, 1945-December 18, 2012. The youngest of the three Gougeon Brothers, Jan was a natural engineer and a visionary. Jan was working in the shop until a few days before his death. Boats he designed and built include WEE THREE, FLICKA, SPLINTER, OLLIE, POCKET ROCKET, MAGIC CARPET, and STRINGS. He was the DN Iceboat World Gold Cup Champion in 1975, 1982, 1985 and 1991; the Great Cup of Siberia in 1989 and the DN North American Championship in 1971, 1972 and 2000. He was also a licensed airplane pilot and an all around great guy. We miss him.

January 2013

Tech Building

The Gougeon technical staff moves into their new building. The facility includes a large, adaptable workshop and a climate-controlled lab. An independent “floating” concrete slab isolates the company’s MTS hydraulic mechanical testing machines from outside vibration interference. The building is dedicated to the memory of Jan C. Gougeon.

October 2015

Hall of Fame

Meade and Jan Gougeon are inducted into The National Sailing Hall of Fame (NSHOF) in October of 2015. Meade and Jan, along with their brother Joel, founded Gougeon Brothers, Inc. in 1969. The two brothers were selected because of their pioneering work in the use of epoxies for boat construction, and because each is an accomplished sailor.

December 2015

Oracle Team USA

ORACLE TEAM USA uses PRO-SET adhesives by Gougeon Brothers, Inc. in the construction of their 2017 America’s Cup contender. Ian Burns, performance team manager for ORACLE TEAM USA, says these adhesives are used to build high-quality small parts. The individually crafted components are joined to the boat with epoxy adhesives, becoming the strongest part of the hulls. Floor manager Johnathan Holstrom points out the adhesives are what ORACLE TEAM USA counts on to hold everything together. He calls PRO-SET epoxies “the nuts and bolts,” in the construction of these state-of-the-art race boats.

July 2016

Adagio Win

Still formidable after 46 years, ADAGIO takes a victory in Division III of the 2016 Bell’s Beer Bayview Mackinac Race. She’s crewed by Alan Gurski, Matt Scharl, and Ben Gougeon. ADAGIO’s longevity is a testament to wood/epoxy boat building. She is the first large wooden boat bonded entirely with epoxy and without mechanical fasteners. She is also the first wooden boat completely sealed with epoxy inside and out. At the time of the 2016 win, she is 47 years old.

March 2017

Elderly Care

Meade Gougeon, 78, places 2nd in his class in the 2017 Everglades Challenge aboard his outrigger sailing canoe ELDERLY CARE. The grueling 300-mile race may have been the toughest in 15 years. “Three days of high winds, headwinds, and rough seas. It was wet and bumpy,” is how Meade describes it. More than half of the 108-boat fleet dropped out, with just 51 entrants making it across the finish line ahead of the 8-day time limit.

August 2017

Meade A. Gougeon

September 25, 1938-August 27, 2017. The eldest of the three Gougeon Brothers was a pioneer in wood/epoxy engineering, an avid multihull sailor and the father of 10. His trimaran Adagio is believed to be the first wood-epoxy boat built entirely without fasteners, and is still winning races today. Meade won the US DN Iceboat Championship in 1981 and 1997, and placed first in his class in the grueling 300-mile Everglades Challenge in 2014 and 2017. In 2015, was inducted, along with his brother Jan, into to National Sailing Hall of Fame.

March 2018

Entropy Resins

Gougeon Brothers Inc. acquired Entropy Resins, bio-based epoxy formulator of adhesives, coatings and composites that maximizes renewable ingredients. Entropy Resins pioneered the use of the USDA’s BioPreferred labeling program to quantify rapidly renewable feedstocks. “Over the last decade we have admired Entropy Resins as they grew from a great idea into a best-in-class bio-based epoxy brand,” said Alan Gurski, president and CEO of Gougeon Brothers Inc. “We share their values of high-performance products and long-term sustainability.”

August 2019

GBI Celebrates its 50th Anniversary

Gougeon Brothers, Inc. celebrates its 50th year in business. And there is so much to celebrate! The company manufactures WEST SYSTEM, PRO-SET, and Entropy Resins epoxies, all of which are sold worldwide. They consult for high-end composites builders ranging from the builders of America’s Cup boats to the U.S. Navy. Their employee-owners know it’s a great place to work.